About Cases24

Cases24 is a manufacturer of high-volume glued cases to the trade. The business is entirely focused on trade customers, typically merchants or distributors. To retain a volume focused setup, the minimum order quantity is 5,000m2.

Aligned with the Board24 corrugators and on the same factory floor, Cases24 is fully integrated with the sheet production at Coalville. Ensuring a smooth transition of orders from sheet to conversion, palletising to loading and delivery.

Customer Collaboration

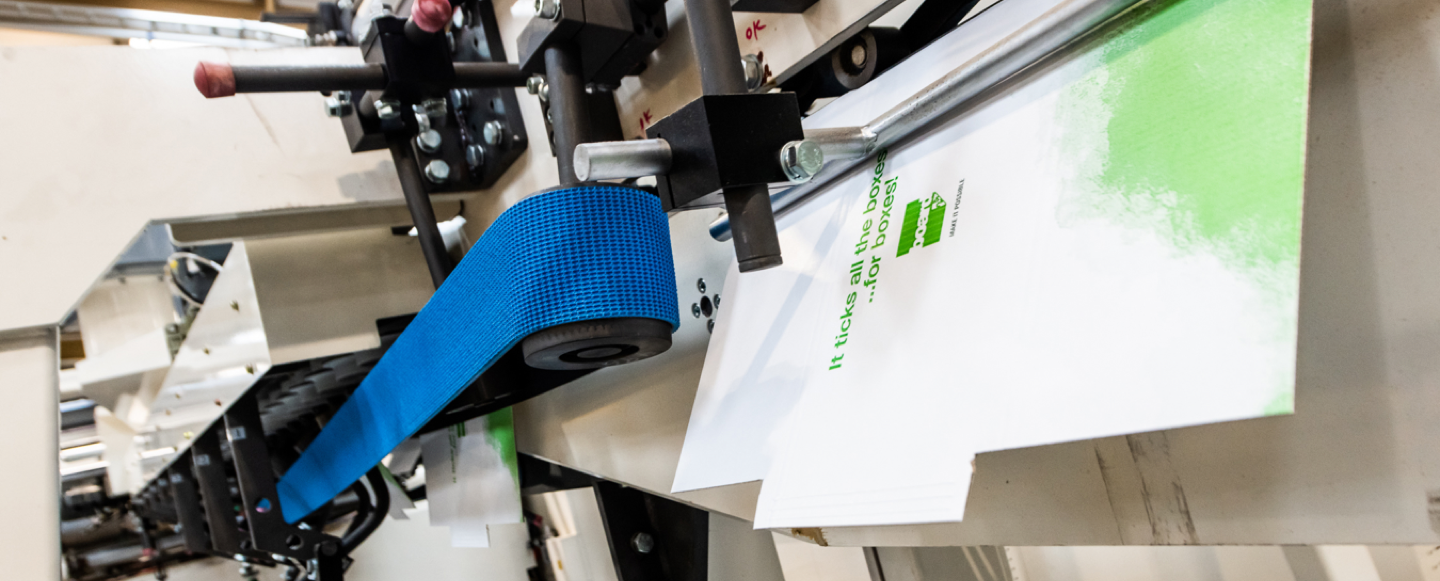

Years of consistent investments in Cases24 has led to a combination of four highly efficient casemakers, in an automated environment, operating 24 hours a day. The undoubted benefit of a site with significant capacity is a favourably flexible service, enabling us to help with any requirement.

Future success depends on our customers and we build true partnerships to create trusting, mutually beneficial relationships. Naturally, this does not just come from our unquestionably high levels of service, also our commercial collaborations for the benefit of the partnership.

Choice

Paper combinations to match product protection – our approach is to meet performance requirement, quite often bespoke combinations of papers based on the board grade suggestions from our experienced laboratory team.

Customer led bespoke paper combinations for your board grades are a measure of the flexibility and willingness to serve the best value for performance. Where possible we will support trial orders to provide confidence in the choices made.

Quality

Board24 has over 30 years of experience in producing high quality board for their sheet plant customers. Cases24 has benefitted from the consistently high-quality board, with an emphasis on ensuring the board is produced with minimal conversion impact through the casemakers. Frequent laboratory tests and QC checks sustain the expected case performance outcomes.

Considerable print, casemaking and operational experience within the whole Cases24 team compliments the quality of product, process and standards upheld.

Capabilities

Our casemakers are capable of 3 colour print and rotary die cutting for SRP & handle holes. We are best suited with 0201s, however, we can also manufacture 0200, 0202, 0203, 0205, 0209 and 0216 styles of cases. We can manufacture in double wall and single wall, in pallet quantities to suit.

Case size manufacturing varies from small ecommerce cases, such as 6” cube, up to 24x18x18 and beyond. Self-locking bases are available, with numerous styles and designs to save cost on tape. Case perforations are suggested to be in the market leading Speedi-FlareTM style, proving a clean, debris free finish. Other perforation styles are available. Combined with the quality of flood print we can achieve, Cases24 is able to supply stand out cases.

Services

Our CAD room and cases sample service is used by many of our customers, where the final push for an order is required. The full suite of testing facilities is available to help achieve a case performance level. Equally analysing packaging performance to provide our customers information to make informed decisions on appropriate board grade, flute format or case orientation.

Cases24 understand the speed of reaction when generating and sending samples can be critical to winning new orders. Our designers hold a large variety of board grades and realise the importance of producing samples in a timely manner. Typically, samples are delivered within 48 hours of the original request.